The Best Wastewater Lagoon Aerators Available

Other aerators may look similar, but the resemblance stops at the surface. At Environmental Equipment Engineering, we strive to make our Floating Aerators the best in terms of efficiency, performance, and durability.

The Least You Get From EEE is The Best Aerator Available

Industrial Wastewater Treatment can be challenging – but EEE is up to the task of stirring up high-quality wastewater aeration. Among other perks, our technicians have over 46 years of experience in the hand lay-up method of fiberglass modeling. As efficient as our products are, they continue to improve. There’s no better pond, lake, or wastewater lagoon aerator on the market.

Superior Efficiency and Performance

One of the most notable differences between our Surface Aerators and our competitors’ is efficiency. When it comes to aeration for wastewater, EEE aerators have pumping flow rates 30% higher than flow rates published by other manufacturers.

As a result, in one recent comparison, a 20 hp EEE USA aerator delivered 15,365 gallons per minute. Comparatively, a competitor’s 20-hp unit pumped 8,321 gallons. The high potency of EEE units also translates to significantly smaller operating costs.

On Mechanical Surface Aerators intake and outtake openings are larger than those of competing models. This allows for better surface aeration efficiency, higher volume oxygen transfer, and more efficient wastewater treatment.

The interior surface of the aerator is perfectly smooth and forms a graceful, natural radius. Water approaches the intake evenly from all directions. No angles or rough edges are encountered. As water passes through, turbulence and exit losses are reduced to almost nothing. Our surface aerator also has a larger diffuser. The larger diffuser provides more surface for the water to follow. Water rushes out in a high-velocity spray pattern. This forms a storm-like wave action, increasing the diameter of mixing, oxygen dispersion, and transfer.

Due to the superior design of our aerator, the motor also operates more efficiently. A 20-horsepower motor on an EEE Floating Aerator will pump almost twice the amount of water of a 20-horsepower motor on a competitor model.

- Since our aerators will pump more water than other models, the rate of oxygen transfer increases by 30 — 40%

- More potent aeration also means shortened retention times.

- As there is little spray back to cause corrosion or freezing, there is virtually no chance of motor failure.

Durability

EEE Floating Aerators are built to last.

The Perfect Mold

For both performance and durability, the starting point for our Floating Aerators is a perfect mold. We’ve spent many years perfecting the molds in which we manufacture our floats and diffusers. The quality of the mold ensures the quality of the final product.

Superior Structural Strength

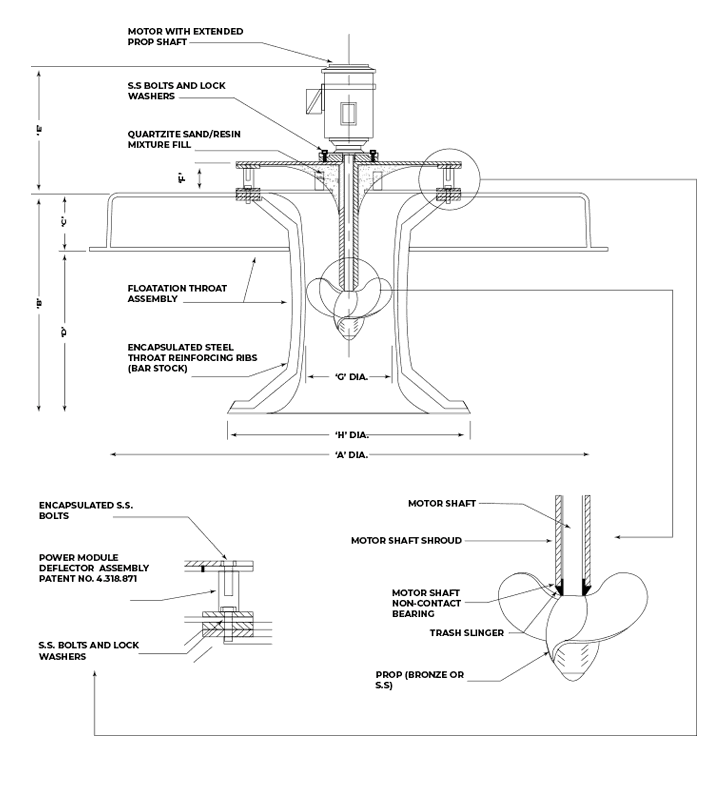

Our craftsmen apply layers of fiberglass by hand. That allows us to use a 45 — 55% glass-to-resin ratio, the ideal mix for optimum strength. The fiberglass on any EEE Floating Aerator will be between one-quarter inch thick and up to three-quarters of an inch thick. We reinforce the throat of the aerator with encapsulated steel ribs. The resins we use are chemical resistant and impervious to sand, grit, and other abrasives.

A More Robust Diffuser

In addition to our superior structural strength, we make the diffuser far heavier (up to 400% in some instances) than competitor models. For example, a 40-horsepower aerator from EEE includes a diffuser that weighs 900 pounds. The weight of competing diffusers for a 40-horsepower aerator is approximately 200 pounds. Another example is that on our 5-horsepower unit, the diffuser weighs 187 pounds. The weight of one of our competitors on a 25-horsepower aerator is 150 pounds.

Reduced Vibration

The heavier diffuser significantly reduced vibration. The industry-accepted level for aerator vibration is 2.0 ml, peak to peak. Our lagoon aerator balances out at a considerably better .2ml, peak to peak.

Another reason vibration is so low on our aerators is that we mount the motor base to the diffuser top. Unlike some competitors’ models, which mount a motor on four posts, our motors rest on the diffuser with a 360-degree machined indexed bit.

Reduced vibration means the EEE Floating Lagoon Aerator will operate trouble-free for much longer periods than other models, plus provide better aeration in general.

Superior Design

Utilizing computer-aided design and unitized fiberglass construction. The EEE Floating Aerator has the smoothest curved intake, volute, and discharge passage of any surface lagoon aerator. The naturally curved intake bell-to-volute-to-discharge design promotes the highest gallon-per-minute rating of any aerator on the market. Less efficiently designed competing aerators actually retard water flow and efficient oxygenation. The EEE diffuser is not only 150% to 400% heavier but also larger in diameter to eliminate spray-back. Spray back that could otherwise freeze and corrode the motor.

All EEE aerators have large diffusers. This is the result of extensive aeration engineering research. These diffusers offer a number of important advantages:

- The large EEE diffuser provides more surface for the water to follow

- The spray is less susceptible to wind drift

- The heavy-duty construction of stainless steel and fiberglass reinforced resin makes it 150% to 400% heavier than diffusers found on competitive aerators.

- The weight of the EEE diffuser minimizes vibration. Such that it balances out below 0.20 mils vibration peak to peak. This is significantly better than the 2.0 mils level considered acceptable throughout the aerator industry.

Propeller Design

Our design also ensures a prominent mixing application of our products. The propeller is designed to pull water and solids from the basin bottom and discharge them out through the aerator diffuser to the surface.

It does this at a 90-degree angle from the motor before being returned into the basin. The wave action induces maximum oxygen and mixing into the basin volume.

The motor’s strength ensures the water can be pulled from all suitable depths for aeration, preventing the sludge from accumulating on the lagoon floor.

Ten Year Warranty

EEE offers a ten-year warranty on all non-moving parts of our Surface Aerators. Any defect or fault of the float or diffuser over a ten-year period will be replaced or repaired at no charge. We also offer a two-year warranty on the motor. This represents a full year over the warranty offered by the manufacturer of the motor. You simply cannot buy a better surface Aerator for your lagoon, lake or pond and you can’t get a better warranty. Here’s what one engineering firm has to say about the EEE floating aerator.

“ We have specified and observed the operation of your products in many varied installations. We do not know of a failure at any of these installations due to aerator design or construction. The units have all operated excellently and, to our knowledge, none have required warranty service or replacement”

At EEE, we are very confident about the performance and durability of our products. Therefore, we have a special treat for our curious competitors – we offer to put our products for testing up against anybody else’s aerators.

The challenge, which is published nationally and repeated here, is for a side-by-side comparison of surface aerator performance. It would be carried out by an independent, impartial engineering firm in a neutral facility. The losing side would pay for the cost of the testing. Sadly, for now, there have been no takers, leaving our aerators hungry for the win.

Wastewater Treatment: Why Is Aeration Important?

Aeration is essential to maintain water quality. In terms of wastewater application, aeration ensures the desirable aerobic decay of the waste material.

Earth’s natural materials and organisms either inhabit or enter small water bodies – even wastewater lagoons and treatment ponds – through various means, including air. As these organisms begin the decaying process, they use up vital oxygen supply and release toxins. These toxins contaminate the water. The problem is amplified when certain microorganisms begin to multiply in what to them is favorable circumstances, leading to a rapid loss of dissolvable oxygen.

As a real-life, easy-to-imagine example – we’ve all seen beautiful ponds, lagoons, and lakes that were unfortunately not well-tended. Soon enough, they would turn into an unsightly swamp-like area with thick algal growth on the water’s surface. The smell that spreads around them is usually unpleasant because of gasses that build up in a low-oxygen environment.

Mechanical aeration can prevent this decline and help maintain water quality. Motor-driven floating aerators are among the most reliable ways to get the much-needed oxygen into the water – and fast.

We know our products

At Environmental Equipment Engineering we have one purpose. That is to continue making the best wastewater treatment, pond, lake, and lagoon mechanical aerators in the world – and without false modesty, we believe we do.

We’ve checked – there is no floating aerator with a more efficient design, higher pumping rate per horsepower, or durable construction that we know of. No aerator has a longer warranty.

That’s why so many facilities prefer our floating mechanical aerators & mixing systems over others.

FAQ’s

Why is aeration important for wastewater treatment?

Oxygen is an essential component of biodegradation – it is required by aerobic bacteria to degrade the waste material. Aerobic degradation – the type conducted by microorganisms in the presence of oxygen – is an elegant and swift process. In the absence of oxygen, these bacteria can’t survive and are replaced by anaerobic bacteria (the ones that thrive without oxygen). Anaerobic or septic degradation conducted by these organisms is very slow, smelly, and inefficient, plus releases undesirable by-products such as methane gas.

How does surface aeration work?

Surface aeration emulates what nature does, only better and stronger. Natural mechanical aeration is promoted by natural water movement, wind, precipitation, and animal activity – all these events break the water’s surface, allowing the precious oxygen to enter. In the absence of these activities or in cases of nutrient or waste overload that surpass natural oxygenation abilities, mechanical aerators vigorously break the surface water tension to bring in oxygen, plus mix the water within the water column. That action prevents the bottom layers of the water from becoming oxygen-deprived.

When is aeration used?

Aeration is used when you need additional oxygen in a pond due to nutrient overload (usually manifesting itself as surface algae bloom) and lack of natural water movement, or dissolved nutrients and waste material in the wastewater. That means that mechanical aeration is used both in regular decorative and other ponds and lakes with clean water to keep them clear, as well as in wastewater and sewage ponds and lagoons to enhance the process of biodegradation. The more oxygen the “good” bacteria have, the quicker the degradation process. That is why aerators have a pivotal role in keeping wastewater ponds efficient and odor-free.

Contact Us Today

Does your water look lifeless or murky?

- Have you noticed decay or algae growth at the surface or perimeter of the water?

- Is the lagoon or pond deep enough for colonies of fish to inhabit?

A problem does not need to arise in order to consider the possibilities and potential of a high-quality pond, lagoon aeration system.

EEE manufactures a full range of Floating Aerators, Wastewater Lagoon Aerators, Mixers, Submersible Aerators, Dual Speed, and Stainless Steel Models to facilitate effective and efficient aeration.

We also supply wastewater treatment products including oil water separators and first flush systems. Click on the links on the right to see spec sheets for our range of products or Contact Environmental Equipment Engineering today.